Comprehensive Steam & Condensate Solutions for Industrial Efficiency

At Susham Solutions, we offer a complete range of steam and condensate systems tailored to meet the diverse needs of industries like pharmaceuticals, textiles, food processing, and power generation. From efficient steam generation to seamless condensate recovery, our solutions are designed to optimize energy use, reduce costs, and enhance operational performance.

Optimized Steam Distribution Systems

Our steam distribution solutions ensure efficient distribution of steam from the boiler to the point of use, minimizing energy loss and maintaining pressure levels.

Product Categories:

1. Isolation Valves:

Gate Valves

Designed for minimal pressure drop and full open-close operations in steam and condensate lines.

Globe Valves

Enable precise flow control and throttling in high-temperature steam applications.

Piston Valves

Provide leak-proof sealing and durability for high-pressure steam systems.

Bellow Seal Valves

Offer zero leakage and long-term reliability in critical steam applications.

2.Safety Valves:

Bronze Safety Valves

Compact, corrosion-resistant safety valves ideal for low to medium pressure systems.

Cast Iron Safety Valves

Robust and economical choice for general-purpose industrial steam safety.

Cast Steel Safety Valves

Engineered for high-pressure, high-temperature environments with durable construction.

Stainless Steel Safety Valves

Offer excellent resistance to corrosion and are ideal for hygienic and aggressive environments.

3.Flow Meters:

Electromagnetic Flow Meters

Highly accurate flow measurement for conductive fluids in industrial steam setups.

Vortex Flow Meters

Versatile meters suitable for steam, gas, and liquid measurement with low maintenance.

Mechanical Turbine Flow Meters

Reliable, cost-effective solution for measuring flow in clean, low-viscosity steam systems.

4.Pipeline Accessories:

Y-Type Strainers

Protect system components by filtering debris from the steam line before it reaches valves or traps.

Moisture Separators

Remove entrained moisture to ensure dry steam reaches the point of use.

Air Vents

Efficiently discharge trapped air during system startup to improve heat transfer.

Non-Return Valves

Prevent backflow and protect equipment in condensate and steam return lines.

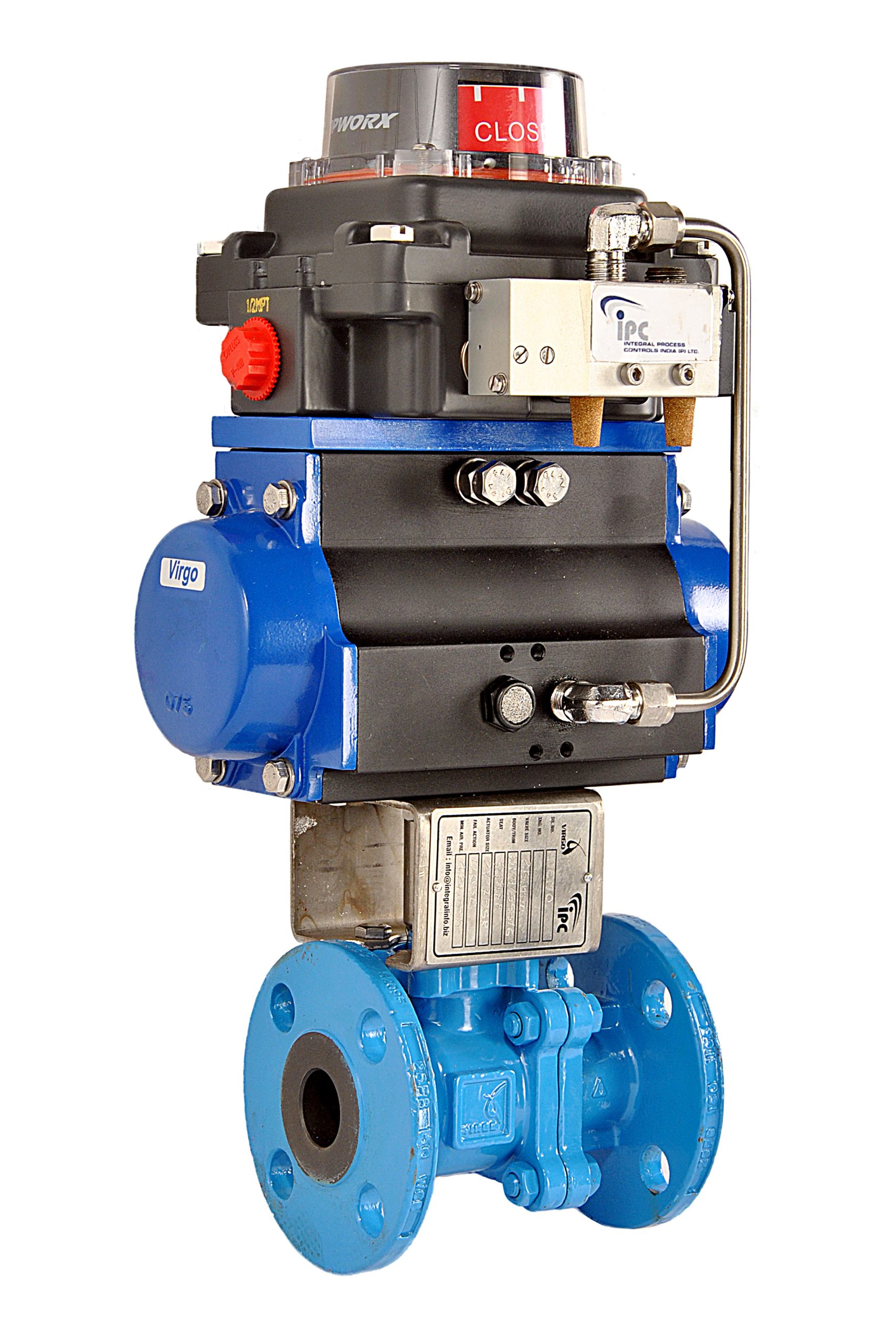

Directional Control Valves

Enable precise directional control in pneumatic and steam automation systems.

Butterfly valves

Fusible Plug

Check Valves

Complete range of check valves available to suit any application.

Diffusers

Create a safe and silent environment when discharging to atmosphere, essential for Health and Safety compliance.

Hosedown Stations

Wall mounted unit that allows steam to mix with cold water to provide a hot water source for hosing down.

Pressure and Temperature Gauges

Range of pressure and temperature gauges to suit any application, including a hygienic option.

Separators

Separators - designed to gather small water droplets from steam & separate them from the pipeflow.

Sight Glasses

Sight glasses allow quick and easy visual inspection throughout your system.

Strainers and Filters

High efficiency steam strainers and filters for better quality steam.

Vacuum Breakers

Used to break the vacuum in a system when the system pressure drops below atmospheric pressure.

Maximizing Steam Usage for Industrial Processes

Our process utilization solutions are designed to optimize steam usage, ensuring efficient and cost-effective operations in critical processes.

Product Categories:

1. Control Valves:

Electro Pneumatic Control Valves

Enable precise modulation of steam flow using pneumatic actuation and electronic signals for high-accuracy control.

Solenoid Operated Valves

Provide quick, automated on/off control of steam and condensate flow in compact setups.

On/Off Control Valves:

Simple yet effective solution for binary steam control in batch and cyclic process applications.

2. Process Traps:

Ball Float Steam Traps

Ensure continuous drainage of condensate while retaining steam, ideal for processes with steady loads.

Inverted Bucket Steam Traps

Robust and energy-efficient design for intermittent condensate discharge in varying load conditions.

Balanced Pressure Steam Traps

Balanced pressure thermostatic steam traps adjust automatically to varying steam pressures.

Bimetallic Steam Traps

Bimetallic steam traps can conserve energy by discharging sub-cooled condensate in those applications which utilise sensible heat.

Sealed Steam Traps

Replacement sealed traps utilise a non-remakeable joint, eliminating the risk of leaks to atmosphere.

Swivel Connectors and Traps

Our range of connectors significantly reduce installation time, cuts costs dramatically, and eliminate system leaks.

Thermodynamic Steam Traps

Thermodynamic steam traps combine reliability, simplicity and efficiency of operation.

Seamless Condensate Recovery Systems

Our condensate recovery systems help industries reduce energy loss, improve efficiency, and lower operational costs by reclaiming steam condensate for reuse

Product Categories:

Steam Operated Condensate Pumps

Efficiently recover and transfer condensate.

Automatic Pumping Traps

Combine the benefits of traps and pumps for seamless recovery.

Flash Jet Pumps

Recover flash steam and improve energy utilization.

SpiraxSarco product

Efficient Steam Generation Solutions

Our steam generation systems are engineered for safety, reliability, and high thermal efficiency. Designed for diverse industrial applications, these systems ensure consistent steam supply while reducing energy consumption.

Product Categories:

IBR Boilers

Compliant with Indian Boiler Regulations for safe and efficient high-capacity steam generation.

Non-IBR Boilers

Compact solutions for smaller operations with lower steam requirements.

Water Tube Boilers

High-pressure systems for industries requiring rapid steam generation.

Fire Tube Boilers

Cost-effective systems for moderate pressure needs.

Waste Heat Recovery Boilers (WHRB)

Maximize energy recovery from industrial waste heat

Thermic Fluid Heaters & Hot Water Generators

Precision heating solutions for various industrial processes.