Waste Water Management (STP)

Why Johkasou-STP is the Most Suitable Wastewater Treatment Solution for India

The Johkasou Sewage Treatment Plant (STP) presents a highly suitable and future-ready solution tailored to India’s unique needs and infrastructure challenges. Unlike conventional wastewater treatment systems, Johkasou-STP offers distinct advantages in terms of modularity, scalability, and operational efficiency.

Key Advantages Over Conventional Systems

- Modular & Scalable: Easily deployable block by block or building by building, making it ideal for both urban and semi-urban settings. The system can grow with increasing demand.

- Low CAPEX & OPEX: Designed for affordability, Johkasou systems require minimal capital investment and offer significantly lower operational costs over time.

Advanced Features & Benefits

- High-Performance Treatment: Delivers consistent, reliable wastewater treatment even in variable load conditions.

- Ease of Maintenance: Equipped with a spacious sludge separation box, enabling convenient sludge collection during routine maintenance—typically required just once every six months.

- Customizable Output Capacity: Available in three models to meet diverse wastewater treatment needs.

- Nutrient Removal: Effectively eliminates harmful nutrients, improving water quality and reducing environmental impact.

- Energy Efficient: Operates on low power, making it environmentally and economically sustainable.

- Long Lifespan: Built for durability and long-term service, with consistent performance across its lifespan.

An Overivew of Wastewater Treatment Processes

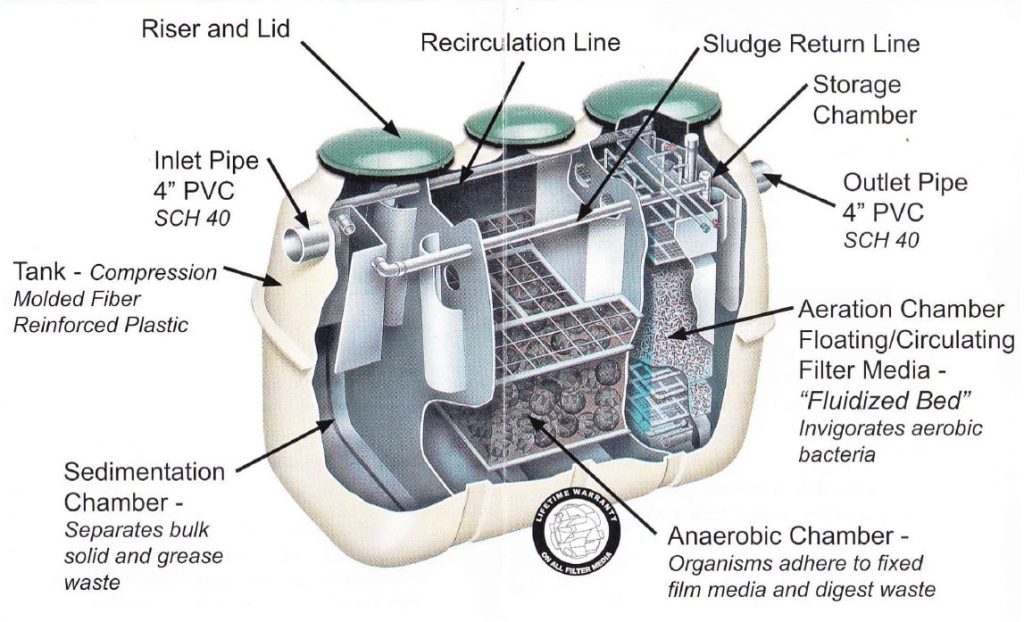

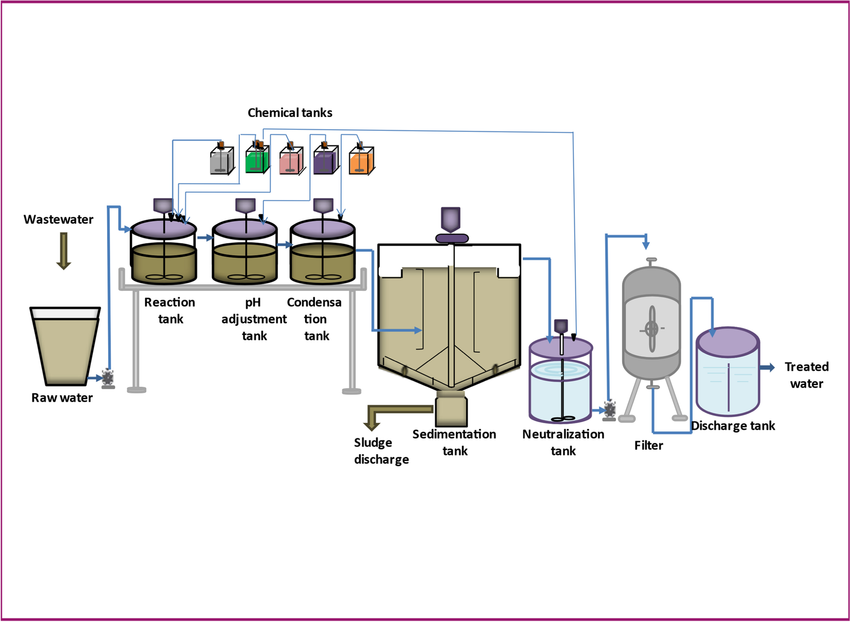

Preliminary Treatment

- Objective:To remove large solids and debris to protect downstream equipment.

- Process:Wastewater flows through progressively finer screens, which filter out materials like plastics, rags, and large particles

- Outcome:Prevents clogging and damage in pumps and piping

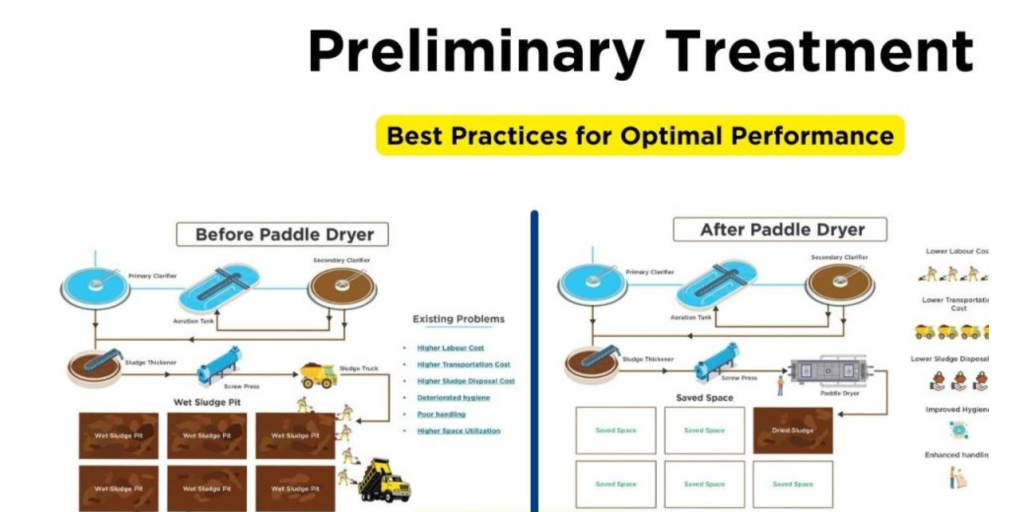

Primary Treatment

- Objective:To settle out solids and reduce organic load.

- Process:

- Wastewater enters a sedimentation tank.

- Sludge collection mechanisms at the bottom remove heavier solids.

- Lighter materials float and may be skimmed off.

- Clear water flows over the effluent weir.

- WAS (Waste Activated Sludge) is removed for further treatment.

- Outcome:Removes ~60% of suspended solids and ~30–40% of BOD (biochemical oxygen demand).

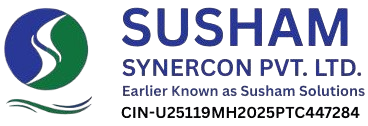

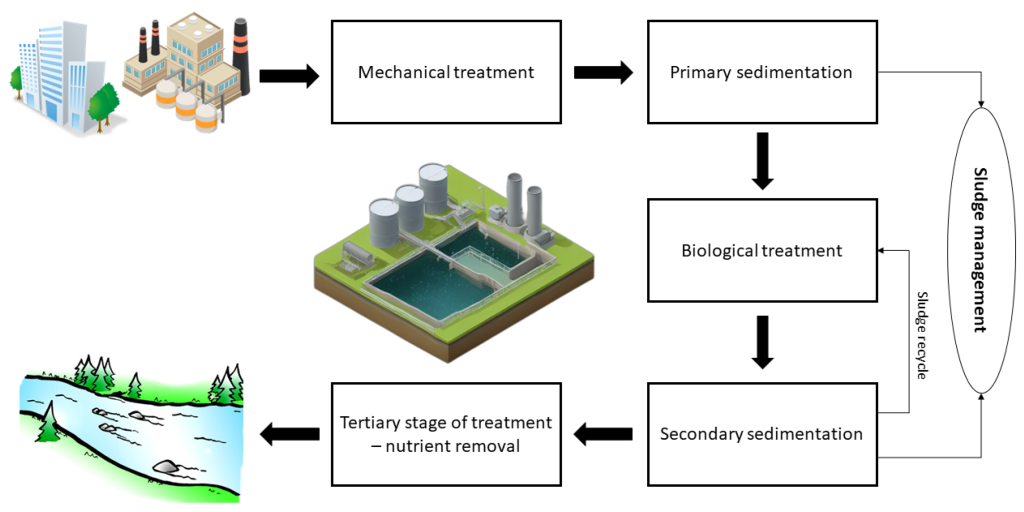

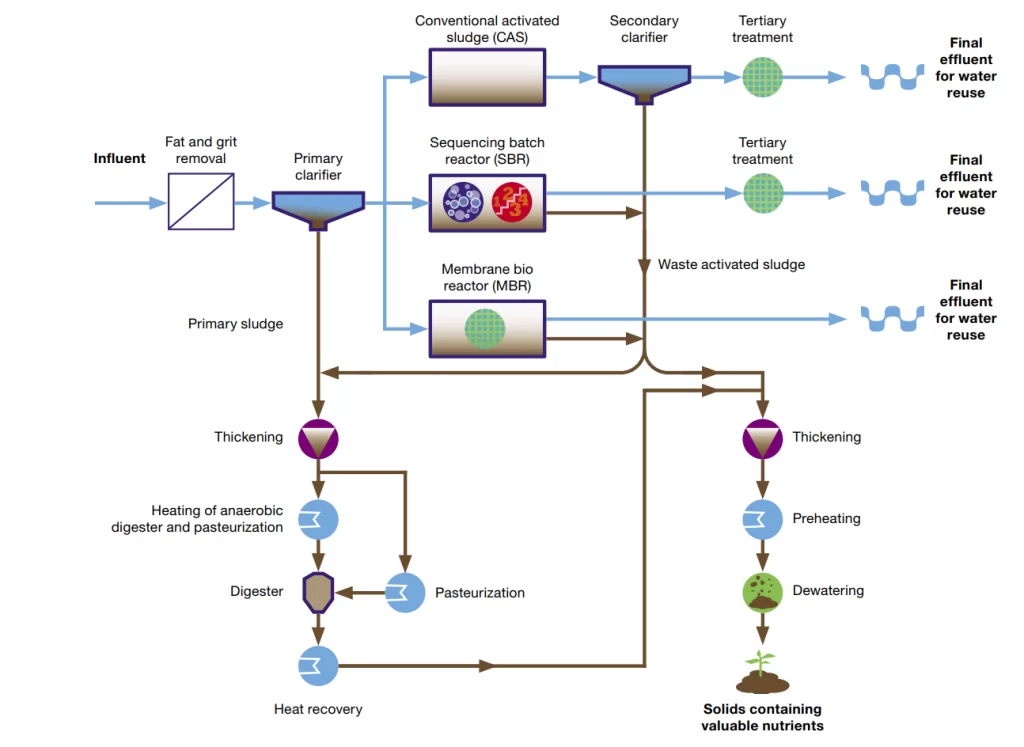

Secondary Treatment

- Objective:To biologically treat wastewater and remove dissolved and suspended organic matter.

- Process:

- Microorganisms break down organic matter in an aeration basin or bio-reactor.

- Sludge settles in a secondary clarifier.

- Some sludge (WAS) is removed, and a portion is returned to maintain microbial population (RAS – Return Activated Sludge).

- Outcome:Significant reduction of BOD, nutrients, and pathogens.

Tertiary Treatment

- Objective:Advanced treatment to remove residual contaminants, nutrients, and solids.

- Process includes:

- Thickening of remaining sludge.

- Digestion to stabilize and reduce volume.

- Gas utilization, where biogas (e.g., methane) is captured for energy.

- Dewatering to reduce sludge water content before disposal or reuse.

- Outcome:Produces high-quality effluent suitable for reuse or sensitive discharge environments.

Sludge Treatment

- Thickening to reduce volume.

- Anaerobic digestion to stabilize organic matter and generate biogas.

- Gas utilization for energy generation.

- Dewatering to prepare for disposal, composting, or incineration.

Discharge/Reuse

- Objective:Safely return treated water to the environment or reuse it.

- Options:

- Treated water is directed into various multipurpose reuse pathways.

- Reuse options may include agriculture, industry, landscaping, or recharge of water bodies.

- Each pathway has associated treatment requirements and quality criteria based on end-use standards.